Epoxy Flooring & Common Issues

Epoxy Flooring is quickly becoming a popular staple in american homes as the number one flooring solution all around. In this article we will dive into some of the elements of epoxy flooring that most people fail to consider. First let us take you through what an epoxy coating even is.

So What Is Epoxy Flooring?

An epoxy coating is a material that is applied to surfaces in order to protect them from wear and tear, as well as provide a barrier against moisture, chemicals, and other substances. Epoxy coatings are typically made up of two parts: a resin and a hardener. When these two parts are mixed together, they create a tough, durable coating that can adhere to almost any surface.

Epoxy is a complex coating that requires close attention to detail and instructions about the formula to get it to come out right the first time. Are you familiar with epoxy floor coatings? You probably have seen it before without even realizing it. Epoxy floor coatings are commonly used in industrial and commercial settings because of their attractive glossy finish and durability. But what exactly is an epoxy floor coating?

Many of us know that it is a type of floor coating, but do you know what epoxy is made of? In this article, we will take a closer look at the chemical makeup and formula of an epoxy floor coating and common issues you may encounter with epoxy flooring.

Facts about Epoxy

Epoxy floor coatings are made from a mixture of two parts: a resin and a hardener. The resin is usually a liquid that is derived from petroleum, while the hardener is typically a crystalline powder. When these two parts are mixed together, they create a chemical reaction that causes the mixture to harden into a durable, glossy finish. With that said, there are different types of resins and hardeners that can be used to create epoxy floor coatings. The combination of these ingredients will determine the final properties of the epoxy coating. For instance, the ratio of resin to hardener can be adjusted to create a harder or more flexible finish. In addition, different types of fillers can be added to the mixture to create a variety of textures.

The Benefits of Epoxy Floor Coatings

Now that we know a little bit more about what epoxy is let's take a look at some of the benefits of epoxy floor coatings. As we mentioned earlier, one of the biggest advantages of epoxy floor coatings is their durability. This type of flooring is resistant to many chemicals, oils, and other liquids that can damage other types of flooring. In addition, epoxy floor coatings are also very easy to clean and maintain. They are often used in commercial kitchens and industrial settings because they can withstand high traffic and heavy equipment. Another benefit of epoxy floor coatings is that they are slip-resistant. This feature is especially important in wet or oily environments.

Epoxy Floor Coating Installation

If you are interested in installing an epoxy floor coating, it is important to understand the installation process. This type of flooring is typically installed by a professional contractor, but it is possible to do it yourself if you have the proper equipment and training. Here are the basic steps involved in installing an epoxy floor coating:

1. Prepare the surface: The first step is to make sure that the surface is clean and free of any debris. Any cracks or holes should be repaired before the epoxy coating is applied. Cleaning the surface is also important because it will help the epoxy to adhere properly.

2. Mix the epoxy: The next step is to mix the resin and hardener together. It is important to follow the manufacturer's instructions carefully so that the chemical reaction occurs properly. Failing to mix the epoxy properly can result in a poor-quality finish.

3. Apply the epoxy: Once the epoxy is mixed, it is time to apply it to the surface. This can be done with a brush, roller, or sprayer. The thickness of the coating will depend on the manufacturer's specifications. The epoxy should be allowed to dry for the recommended amount of time before traffic is allowed on the surface.

4. Apply a topcoat: In some cases, a top coat may be applied to protect the epoxy floor coating from UV rays and other elements. This step is not always necessary, but it can extend the life of the coating. Top coatings are typically clear and provide a glossy finish.

If you follow these steps, you should be able to install an epoxy floor coating without any problems. However, it is always best to consult a professional contractor to make sure that the job is done correctly.

Is Epoxy Flooring Expensive?

The cost of epoxy flooring will vary depending on a number of factors. The size of the area to be coated, the type of epoxy used, and the complexity of the installation are all important factors that will affect the price. In general, epoxy flooring is more expensive than other types of flooring. However, its durability and easy maintenance make it a good investment for many homeowners and businesses, and the initial cost is often offset by the long-term savings.

Knowing about the chemical makeup and formula of epoxy resin floor coatings is important for those who are interested in this type of flooring. This type of coating is known for its durability and easy maintenance, and it can be a great investment for any home or business.

Understanding the installation process and the cost of epoxy flooring can help you make the best decision for your needs. Always consult a professional contractor to ensure that the job is done correctly. Even with a professional installation you may find that their are issues like thickness, uneven-ness, and peeling; if you do encounter any of these issues don’t worry we have you covered.

Thickness

Many people don't realize that there are different epoxy flooring thickness levels. The thickness level you need depends on the type of epoxy and the purpose of the floor. In this article, we'll show you how to determine which epoxy flooring thickness level is right for your needs.

What Types of Epoxy Flooring Are There?

There are three main types of epoxy: water-based, solvent-based, and 100% solid. Water-based epoxy is the most common type used for residential and commercial applications. It's less expensive than other types of epoxy, and it's easy to apply.

Solvent-based epoxy is more expensive than water-based, but it's more durable and has a higher resistance to chemicals and staining.

100% solid epoxy is the most expensive type of epoxy, but it's also the most durable. It has a higher resistance to chemicals, staining, and UV light.

What Are the Different Epoxy Flooring Thickness Levels?

The thickness level of epoxy flooring is measured in mils (thousandths of an inch). The most common thickness levels are 2, 3, and 4 mils.

2 mils: This is the thinnest layer of epoxy, and it's typically used for residential applications.

3 mils: This is the standard thickness for commercial and industrial applications.

4 mils: This is the thickest layer of epoxy, and it's typically used for industrial applications where there's a lot of foot traffic or heavy equipment.

How Do I Know Which Epoxy Flooring Thickness Level I Need?

The type of epoxy and the floor's intended use are the two main factors that determine which thickness level you need.

If you're using water-based epoxy for a residential application, 2 mils are typically sufficient. For commercial and industrial applications, 3 mils are the standard thickness. And for floors that will see a lot of foot traffic or heavy equipment, 4 mils is recommended.

Keep in mind that the thicker the layer of epoxy, the more expensive it will be. So, if you're on a tight budget, you may want to opt for a thinner layer of epoxy.

When It Comes to Epoxy Flooring, Thickness Matters

The thickness of your epoxy flooring is an important factor to consider when choosing the right floor for your needs. Water-based epoxy is the most common type used for residential and commercial applications, and it comes in different thickness levels.

The type of epoxy and the floor's intended use are the two main factors that determine which thickness level you need. So, be sure to keep these things in mind when selecting the right epoxy flooring for your home or business.

You should also consult with a professional flooring contractor to get expert advice on which epoxy flooring thickness level is right for your project. They can help you choose the right epoxy and thickness level based on your specific needs.

What if I Install Epoxy Flooring that's Too Thick or Thin?

If you install epoxy flooring that's too thick, it may not cure properly. This can cause the floor to become sticky or tacky, and it may not be as durable as a properly cured floor.

If you install epoxy flooring that's too thin, it may not provide the desired level of protection or durability. So, be sure to select the right thickness for your needs.

Installing epoxy flooring is a big investment, so be sure to consult with a professional before starting your project. They can help you choose the right epoxy and thickness level based on your specific needs. With their help, you can ensure that your epoxy flooring is installed correctly and that it will last for many years to come.

What Are the Risks of DIY Epoxy Flooring Installation?

Installing epoxy flooring is a big investment, and it's important to do it right. If you don't have experience installing epoxy floors, it's best to leave it to the professionals.

There are a few risks associated with DIY epoxy flooring installation, including:

- Applying the epoxy too thick or too thin

- Not allowing the epoxy to cure properly

- Damaging the floor during installation

These risks can be avoided by hiring a professional flooring contractor to install your epoxy floor. They have the experience and expertise to ensure that your floor is installed correctly and that it will last for many years to come.

On average, the costs to fix DIY epoxy mistakes can range from $500 to $1,500. So, it's best to avoid these mistakes by hiring a professional to install your epoxy floor.

Sealing

Are you unsure whether you should fix an uneven epoxy coating? This is an issue that many people face, but most shy away from because they don't want to make things worse. Luckily, we're here to help! Keep reading to learn more about repairing an uneven epoxy coating.

Why Do Epoxy Coatings Become Uneven?

There are several reasons why an epoxy coating might become uneven. The most common reason is improper mixing of the two components. If the resin and hardener are not mixed together correctly, the resulting mixture will be uneven and will not set properly. Another common reason for an uneven epoxy coating is improper application. If the epoxy coating is not applied evenly, it will dry unevenly and will be more likely to crack or chip.

Should I Fix an Uneven Epoxy Coating?

The answer to this question depends on the severity of the unevenness. If the unevenness is minor, you may be able to get away with simply sanding down the high spots and re-coating the surface. However, if the unevenness is more severe, you will likely need to remove the entire epoxy coating and start from scratch.

How Can I Prevent My Epoxy Coating from Becoming Uneven?

There are a few things you can do to prevent your epoxy coating from becoming uneven. First, make sure that you mix the resin and hardener together correctly. Be sure to follow the manufacturer's instructions carefully. Second, apply the epoxy coating evenly. Use a paint roller or a brush to apply an even layer of the mixture. Lastly, allow the epoxy coating to dry completely before walking on it or putting any weight on it.

By following these tips, you can avoid having to repair an uneven epoxy coating. However, if your epoxy coating does become uneven, don't hesitate to contact a professional for help.

What if My Epoxy Coating Can't be Repaired?

If your epoxy coating is severely damaged or if it cannot be repaired, you may need to replace it. The best way to do this is to hire a professional who has experience with epoxy coatings. They will be able to remove the old coating and apply a new one quickly and efficiently.

Replacing an epoxy coating can be a daunting task, but it's important to remember that it's not impossible. With the help of a professional, you can have a new epoxy coating that looks as good as new in no time!

Best Practices for Repairing an Uneven Epoxy Coating

Now that you know more about repairing an uneven epoxy coating, it's time to put that knowledge into practice! Here are a few best practices to keep in mind.

First, you should always consult with a professional before attempting to repair an uneven epoxy coating. They will be able to assess the damage and give you specific instructions on how to proceed.

Next, if you decide to repair the coating yourself, be sure to follow the manufacturer's instructions carefully. This will ensure that you mix the resin and hardener correctly and that you apply the epoxy evenly.

Finally, remember to allow the epoxy coating to dry completely before walking on it or putting any weight on it. This will help prevent further damage to the coating.

By following these best practices, you can avoid making a bad situation worse. If you're ever unsure about how to proceed, always err on the side of caution and consult with a professional.

An uneven epoxy coating can be a major annoyance. However, it's important to remember that it's not the end of the world. With a little bit of knowledge and the help of a professional, you can easily repair an uneven epoxy coating. Just be sure to follow the manufacturer's instructions carefully and to allow the epoxy plenty of time to dry before using it.

Over the years we here at epoxy flooring anaheim have gotten hundreds of questions about epoxy flooring and all of its elements, here are a couple of popular questions that we get.

Q: Can an uneven epoxy coating be repaired?

A: Yes, an uneven epoxy coating can usually be repaired. However, the severity of the damage will determine how easy it is to repair.

Q: What if my floor is very uneven?

A: If your floor is very uneven, you may need to replace the entire epoxy coating. While this is common, it's important to consult with a professional before attempting to do this yourself.

Q: How can I prevent my epoxy coating from becoming uneven?

A: There are a few things you can do to prevent your epoxy coating from becoming uneven. First, make sure that you mix the resin and hardener together correctly. Be sure to follow the manufacturer's instructions carefully. Second, apply the epoxy coating evenly. Use a paint roller or a brush to apply an even layer of the mixture. Lastly, allow the epoxy coating to dry completely before walking on it or putting any weight on it.

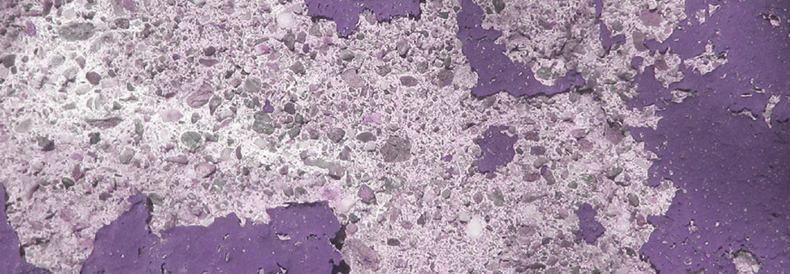

Alongside thickness and un-even coatings many people notice that (if poorly installed) the epoxy flooring will begin to peel. This may start small but it can become a big issue very quickly.

Peeling

How does epoxy flooring peel over time? There are several conditions that may cause the epoxy to peel over time. In this article, we'll look at some of the most common reasons and solutions. We'll also discuss acid etching and profiling. You'll want to follow these steps to avoid this problem. In the end, you'll have a beautiful floor that lasts for many years!

Conditions that Cause Epoxy Flooring to Peel

In general, conditions that cause epoxy flooring to peel over time are not related to the coating itself. These problems can be caused by improper preparation, which can result in bubbles and blisters. There are several factors to consider before applying an epoxy floor. Proper preparation is crucial to a long-lasting finish, so it's best to use a professional.

A qualified epoxy floor applicator will first assess the subsurface conditions, mix the correct resin and hardener ratio, and ensure proper air entrainment. In addition, unqualified individuals are less likely to apply the coating properly.

One of the reasons why epoxy coatings peel is due to poor preparation. The surface must be clean and porous to adhere to the coating properly. If it's not, the epoxy coating will just peel away with the concrete. Poor quality concrete slabs may be the cause of peeling epoxy. Poorly-mixed concrete, improper curing, or poor workmanship could all contribute to this problem.

Besides being easy to install, epoxy flooring is extremely durable. The chemical compounds in it create a floor that resists shock and heat while also being aesthetically pleasing. In addition, the product can be coated with an anti-slip coating to prevent slipping and falls. Epoxy flooring is an excellent solution for companies in a range of industries, including meat and poultry, electronics, and pharmaceutical.

Acid Etching

Several factors contribute to the peeling and cracking of epoxy flooring. The first is moisture. If water is allowed to sit on the surface of the concrete slab, the epoxy will not adhere to the surface. Another factor is improper floor neutralization. Fortunately, there are several solutions to the problem.

Acid etching can cause your flooring to peel over time, so use the right product to get a smooth surface. To prevent etching, you need to use a cleaner that contains a mild acid. Make sure to use a neutralizing solution for spills or stains. If you do get any acid on your floors, neutralizing them with a neutralizing solution is crucial.

Another cause of epoxy peeling is improper floor preparation. If you do not prepare the concrete floor properly, the epoxy will not adhere to it. In addition to being too dirty, the concrete floor may have been acid etched and cannot be properly prepared. This may have also caused loose concrete dust to sit on top of the floor. These two conditions can prevent the epoxy from properly bonding with the concrete. As a result, the epoxy will peel off soon after applying it.

Profiling

The process of profiling your epoxy flooring requires a certain level of expertise, a skill that is best acquired by a professional. The most important aspect of this process is proper concrete preparation. Poorly prepared concrete is one of the major reasons why epoxy floors fail. Acid etching is the process of opening the concrete pores to create a rougher surface. This type of surface profile is essential for coatings that are thicker than paint.

For a proper epoxy coating, the concrete surface must be roughened so that the coating will adhere properly. This process is often done with chemical or mechanical means. By profiling the surface of the concrete, you ensure that the coating will have something to "bite" onto. In addition to profiling, you must thoroughly clean your concrete to ensure that it is completely clean of contaminants. The coating will adhere to the surface better if the surface is clean and dry.

Temperature

If you are considering installing epoxy flooring on your garage floor, you should know that the chemical reaction of the floor's surface is affected by temperature. As the temperature of concrete decreases over time, the epoxy becomes weak and peels. Nevertheless, you can use rubber mats to protect your floor in case it peels over time. In adhesion tests, high temperatures will cause the floor to lift, but low temperatures won't.

In addition to humidity, the temperature can affect the curing process of your epoxy flooring. When you install your flooring, the temperature of the surrounding environment must be at a suitable level. Cold temperatures will cause your flooring to crack and peel, and the process may take longer. Ensure the floor's temperature remains around 77 degrees Fahrenheit throughout the installation process. If you install the flooring in an area with high humidity, it will take longer to cure.

A poorly prepared concrete surface is another cause for an epoxy floor to peel. The surface profile is important because it determines the mechanical bond between the epoxy and the concrete. Most epoxy has a CSP 1 or CSP 2 profile, and improper surface preparation will result in a peeling surface. Therefore, you must prepare your concrete surface properly. However, if you have a poorly prepared floor, you may have to use acid etching or grinding to get the right surface profile.

Cleaning

Scrubbing an epoxy floor is necessary if it starts to peel over time. Grit and sand are hard to detect, but they can damage the coating over time. To remove dirt and debris, use a soft-bristled brush. Avoid using steel wool or harsh chemicals. It is also important to avoid using vinegar or acid, as these can break down the epoxy catalyst. If the surface is damaged by rust, it is important to follow the instructions listed above to prevent further damage to the epoxy flooring.

Soap-based cleaners leave behind soap scum. These substances dull the gloss of the epoxy coating and can damage the anti-skid properties of the floor. Also, they are dangerously slippery when wet, and every garage floor will get wet from time to time. Using a neutralizing agent is highly recommended. To clean your flooring, use one-third cup of dishwashing soap diluted in four or five liters of water.

Another way to check whether your epoxy is peeling is to use a water-drop test. If a water drop falls onto the area, it will absorb the water and leave the area darker than the surrounding concrete. If the oil-stained area absorbs water, the epoxy will start to peel. In some cases, oil can also damage the surface of the floor. The solution to this problem depends on the type of oil and its location.

Once you know how epoxy can degrade and peel over time, you can take the steps to prevent this damage from happening. There is no reason to live with dull or cracked epoxy floors. One of the most common places that the listed issues occur is in the Garage. In our opinion there is no better flooring option for the garage!

Why is Epoxy Great for Garage Floors?

There are many reasons why epoxy is a great choice for garage floors. First, it is very durable and can withstand a lot of wear and tear. Epoxy is also resistant to oil and chemicals, making it ideal for use in garages. Epoxy floors are also easy to clean and maintain, and they can give your space a high-end look. It is much cheaper than other flooring options, such as tile or stone, and is available in a variety of colors to give you a custom design. Overall, epoxy is a great choice for those looking for a durable and easy-to-maintain floor for their garage.

How to Fix Damaged Garage Epoxy Floors

There are many different types of repairs you can make to your garage epoxy floor. The first step is to identify the type of damage you have. Whether you have small cracks or chips, or large sections that need to be replaced, there are repair methods that can be used to fix your floor.

Repairing Small Cracks and Chips

For small cracks and chips, you can use a repair kit that is specifically designed for epoxy floors. These kits come with everything you need to fix your floor, including the epoxy, primer, and putty knife. Simply mix the epoxy according to the instructions and use the putty knife to fill in the cracks or chips. Once the epoxy has dried, you can sand it down and apply a new coat of epoxy to your floor.

Replacing Large Sections

For large sections that need to be replaced, you will need to remove the old epoxy and apply a new layer. First, use a power washer or stripper to remove the old epoxy. Next, apply a new layer of primer and then epoxy. You can either roll on the epoxy or use a sprayer. Once the epoxy has dried, you can sand it down and apply a new coat of epoxy to your floor.

Upgrading Your Garage Epoxy Floor

Once you have repaired any damage to your floor, you may want to upgrade the look of your space with a new coat of epoxy. Epoxy comes in a variety of colors, so you can choose a color that matches your style. You can also add a variety of design elements to your floor, such as chips or flakes. Upgrading your garage floor with epoxy is a great way to give your space a fresh, new look. Here are some ideas to upgrade your epoxy flooring.

Add a New Color: If you are looking for a new look, you can add a new color to your floor. Epoxy comes in a variety of colors, so you can find the perfect shade to match your style. You can also use epoxy to create custom designs on your floor. Epoxy gives off a high-gloss finish that can brighten up your space.

Add Chips or Flakes: You can also add chips or flakes to your epoxy floor for a unique look. Chips and flakes come in a variety of colors and sizes, so you can create a custom design. You can apply the chips or flakes to the entire floor and give your garage a showroom feel that will make your garage look amazing.

Add a Clear Coat: If you want to protect your floor and make it last longer, you can add a clear coat of epoxy. This will create a barrier that will protect your floor from stains and wear and tear. It is also easy to clean and maintain. A clear coat is a perfect way to upgrade your floor, so it lasts longer.

Garage epoxy floors, and epoxy flooring in general is a great choice for those looking for a durable and easy-to-maintain floor. If you have any further questions, comments, or concerns we would encourage you to give us a call!